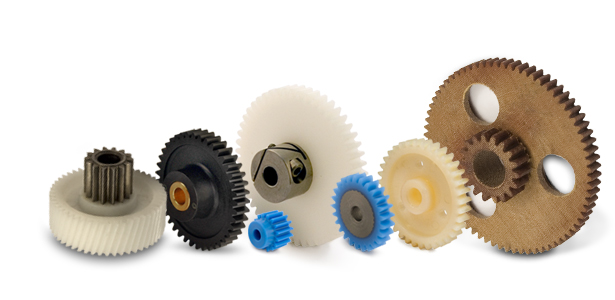

Product Description

uhmw polyethylene wear machined cnc plastic parts

UHMWPE (Ultra High Molecular Weight Polyethylene ) have an average molecular weight more than 3 million .

UHMWPE is a linear polyethylene that is made up extremely long chains of polyethylene which all align in 1 direction .

UHMW-PE is used in a wide variety application. Our main production are UHMWPE Rod, UHMWPE Sheet & UHMWPE Machined Parts with excellent quality and physical properties; also,in various shapes, e.g. Extruded Rod, Extruded Sheet,Extruded Tube & Machined Components according to customer’s demand.

Properties :

Excellent performance on abrasion resistant

High impact strength

Excellent chemical resistant

Do not absorb moisture ,water and chemical liquid .

Food direct safty

Stress crack resistant

Light weight

Excellent electrical properties

Non water absorption

Lowest coefficient of friction

Ease of fabrication

High Sliding & non-stick characteristic

Any Shape is ok ,please offer us accurate size or drawing !

Injection ,or extrusion manufacturing available .

FAQ :

Q1: Are you a manufacturer?

A1: Yes, we have been in providing the professional products

Q2: Is customized available ?

A2: Yes, according to your detailed drawings you provide.

Q3: How to pay?

A3: T/T payment,Trade Assurance and other payment. About the payment details please feel free to contact us. Thank you!

Q4:Can you supply sample?

A4:Yes,we can supply you free small samples,but air cost will be paid by customers.

Q5:How many days will the samples be finished?And how about the mass production?

A5: Generally the samples will be sent immediately by the air express in 3-5 days if the goods are in stock. Normally within 30days or according to your order.

| Application: | Machinery Accessory |

|---|---|

| Surface Treatment: | Polishing |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining |

| Material: | Nylon, Plastic |

| Size: | Customized |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the benefits of using plastic gears over traditional materials?

Using plastic gears instead of traditional materials offers several benefits. Here’s a detailed explanation of the advantages of using plastic gears:

- Weight Reduction: Plastic gears are significantly lighter in weight compared to gears made from traditional materials such as metal. This lightweight characteristic is advantageous in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Noise and Vibration Reduction: Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment. Metal gears, on the other hand, tend to generate more noise and vibration due to their higher stiffness.

- Self-Lubrication: Certain plastic materials used in gears have inherent lubricating properties, allowing for self-lubrication between gear teeth. This reduces friction and wear, eliminating the need for external lubrication and simplifying maintenance requirements. Metal gears, on the other hand, typically require lubrication to reduce friction and wear.

- Corrosion Resistance: Plastic gears can exhibit excellent resistance to corrosion and chemicals, depending on the chosen plastic material. This makes them suitable for applications in corrosive environments where metal gears may suffer from degradation or require additional protective measures.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Cost-Effectiveness: Plastic gears are often more cost-effective compared to gears made from traditional materials. Plastic materials are generally less expensive than metals, and the manufacturing processes for plastic gears, such as injection molding, can be more efficient and economical for large-scale production.

- Electrical Insulation: Plastic gears offer electrical insulation properties, which can be advantageous in applications where electrical isolation is required. Metal gears, on the other hand, can conduct electricity and may require additional insulation measures in certain situations.

- Customization and Color Options: Plastic gears can be easily customized in terms of shape, size, color, and surface finish. This allows for branding, aesthetic preferences, or specific identification requirements in various applications. Metal gears, on the other hand, have more limited options for customization.

These benefits make plastic gears attractive alternatives to traditional materials in many applications. However, it’s important to consider the specific requirements and operating conditions of the application when selecting the appropriate gear material.

What is the impact of temperature variations on plastic gears?

Temperature variations can have a significant impact on plastic gears. Here’s a detailed explanation of their effects:

1. Thermal Expansion: Plastic gears can experience thermal expansion or contraction with changes in temperature. Different types of plastics have varying coefficients of thermal expansion, meaning they expand or contract at different rates. This can result in dimensional changes, which may affect the gear’s meshing, clearance, and overall performance. It’s important to consider the thermal expansion characteristics of the specific plastic material used in the gear design.

2. Material Softening or Hardening: Plastic materials can exhibit changes in mechanical properties with temperature variations. In general, as temperature increases, plastic materials tend to soften and become more flexible, while at lower temperatures, they can become stiffer and more brittle. These changes can impact the gear’s load-bearing capacity, wear resistance, and overall durability. It’s crucial to select plastic materials that can maintain their mechanical integrity within the expected temperature range of the application.

3. Dimensional Stability: Plastic gears may experience dimensional changes or warping due to temperature fluctuations. Higher temperatures can cause plastic materials to deform, leading to misalignment, increased backlash, or reduced gear accuracy. Conversely, lower temperatures can cause contraction, resulting in tight clearances, increased friction, or gear binding. Proper design considerations, including material selection and gear geometry, can help mitigate the impact of temperature-induced dimensional changes.

4. Lubrication and Wear: Temperature variations can affect the lubrication properties of plastic gears. Higher temperatures can cause lubricants to degrade or become less effective, leading to increased friction, wear, and potential gear failure. Similarly, low temperatures can cause lubricants to thicken or solidify, hindering proper lubrication and increasing wear. Selecting lubricants suitable for the anticipated temperature range and periodic maintenance can help ensure proper lubrication and minimize wear on plastic gears.

5. Cold Flow and Creep: Some plastic materials, especially those with lower glass transition temperatures, may exhibit cold flow or creep at elevated temperatures. Cold flow refers to the gradual deformation or flow of plastic material under constant stress, while creep refers to the time-dependent deformation under a constant load. These phenomena can cause changes in gear geometry, tooth profile, or tooth engagement over time, potentially affecting gear performance and functionality. Understanding the material’s creep and cold flow characteristics is important when selecting plastic gears for applications exposed to temperature variations.

6. Impact on Lubricants and Seals: Temperature variations can also impact the performance of lubricants and seals used in gear systems. Extreme temperatures can cause lubricants to break down, lose viscosity, or leak from the gear assembly. Seals and gaskets may also be affected, leading to compromised gear housing integrity or increased friction. It’s crucial to consider temperature compatibility and select appropriate lubricants and seals that can withstand the anticipated temperature range.

In summary, temperature variations can significantly impact plastic gears by causing thermal expansion, material softening or hardening, dimensional changes, lubrication issues, cold flow or creep, and effects on lubricants and seals. Proper material selection, design considerations, and understanding the anticipated temperature range are essential to ensure the reliable and optimal performance of plastic gears in various applications.

What industries commonly use plastic gears?

Plastic gears find applications in various industries due to their unique properties and advantages. Here’s a detailed explanation of the industries that commonly use plastic gears:

- Automotive: Plastic gears are used in automotive applications such as power windows, seat adjusters, HVAC systems, windshield wipers, and various motor-driven mechanisms. Their lightweight nature, noise reduction capabilities, and corrosion resistance make them suitable for these applications.

- Consumer Electronics: Plastic gears are used in consumer electronics devices like printers, scanners, cameras, and audio equipment. Their lightweight construction, low noise generation, and design flexibility make them ideal for compact and noise-sensitive applications.

- Medical: Plastic gears are utilized in medical devices and equipment such as pumps, lab instruments, diagnostic devices, and surgical equipment. Their corrosion resistance, lubricity, and ability to be sterilized make them suitable for medical environments.

- Office Equipment: Plastic gears are commonly found in office equipment like printers, photocopiers, scanners, and shredders. Their low noise operation, lightweight construction, and cost-effectiveness make them popular choices in these applications.

- Industrial Machinery: Plastic gears are used in various industrial machinery applications, including packaging equipment, conveyor systems, material handling equipment, and small gearboxes. Their self-lubricating properties, corrosion resistance, and noise reduction capabilities make them suitable for these industrial environments.

- Toys and Games: Plastic gears are extensively used in toys, hobbyist models, and games. Their lightweight nature, cost-effectiveness, and ease of customization allow for the creation of intricate moving parts in these recreational products.

- Aerospace: Plastic gears are used in certain aerospace applications, particularly in non-critical systems such as cabin equipment, small actuators, and control mechanisms. Their lightweight construction and noise reduction characteristics are advantageous in aerospace applications.

- Telecommunications: Plastic gears find applications in telecommunications equipment such as routers, switches, and communication devices. Their lightweight design, noise reduction properties, and cost-effectiveness make them suitable for these applications.

These are just a few examples of the industries that commonly use plastic gears. The versatility, cost-effectiveness, design flexibility, and specific performance characteristics of plastic gears make them valuable components in numerous applications across various sectors.

editor by CX 2023-10-31