Product Description

| INJECTION MOLDING EQUIPMENT | ||

| ITEM NAME | SPECIFICATION | QUANTITY(SET) |

| American Clamyron Horizontal injection molding machine | 250T | 1 |

| American Clamyron Horizontal injection molding machine | 160T | 1 |

| ZheJiang Yizhan precision Horizontal injection molding machine | 110T | 1 |

| Sumitomo Precision Electric Injection Moldig Machine | 75T | 3 |

| Nissei Precision Electric Injection Moldig Machine | 50T | 4 |

| Xihu (West Lake) Dis. High Speed Precision Vertical Injection Molding Machine | 55T | 2 |

| Xihu (West Lake) Dis.g Servo Manipulator | 15 | |

| Three-in-1 baking material suction machine | 8 | |

| Constant temperature hopper | 10 | |

| Color mixing and feeding machine for injection molding | 5 | |

| TOTAL | 12 sets | |

Product Description

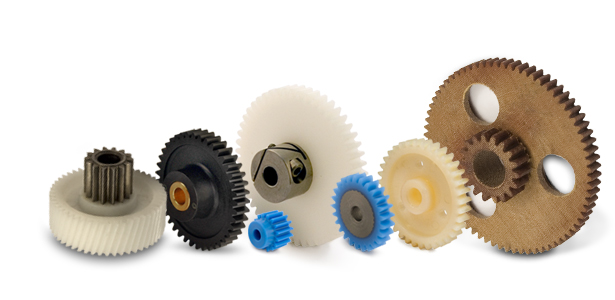

| Product Type | injection molding |

| Mould material | Plastic mould material: P20 steel, 718, 2738, H13, NAK80, 2343, S136 |

| Product Material available | ABS, PP, PA, PMMA, PC, PE, LCP, PA+GF, etc |

| Product’s size available | Minimum: 0.05×0.05×0.05mm Maximum: 180x180x70mm |

| Applications | CCTV/security camera components,IR-cut/optical transceiver |

| Delivery time | 20-25 working days,Mass production: 2-3 weeks |

| Minimum order | Small orders can be accepted |

| Production capacity | 20 sets/month |

| Shipment | by Express: DHL, FedEx, UPS, EMS, etc; by air transport; by sea transport |

1. Professional Manufacturer: All of our Fastener are designed and manufactured according to buyers’ specification and performance.

2. Quality is guaranteed: Durability testing and critical technical design to enhance lifetime.

3. Cost effective: Competitive prices with professional factory supply

4. Perfect solution with rich experiences to solve your problem: Wide range of parts selection.

5. Customized ideal product: customized services according to the samples and drawings offered.

Company Profile

ELMAX was established in 2015, the company is located in Building 1, No. 180, Urban-Rural Road, CHINAMFG Town, HangZhou City,

ZheJiang Province of China. They are 2 factories in Xihu (West Lake) Dis.Guang and ShenZhen manufacturing for ELMAX.

As a one-stop OEM/ODM service provider, CHINAMFG has always been committing to the technology of stamping and plastic injection

molding ; Focusing on metal stamping,hardware,cnc machining and mass production of stamping parts, Injection-molded CHINAMFG and

Insert-molding components. The products range is inclusive of hardware stamping parts, metal stamping, sheet stamping,plastic

injection parts The main customers of CHINAMFG are domestic CHINAMFG companies and partners comes from all of the world especially

from Europe/America.

With competive price, reasonable price and strength technical support, that cause the featured product of metal plastic parts.

After these years′ development, our company has formed an integrated solutions provider, which contains engineering design,

plastic mould, injection moulding parts etc.

Adhering to the principle of quality first, We will win customer satisfaction and make unremitting efforts to win the satisfaction of customers.

Welcome you to establish long term business relationship with CHINAMFG metal&plastic.inciple of quality first, We will win customer satisfaction and make unremitting efforts to win the satisfaction of customers.

Welcome you to establish long term business relationship with CHINAMFG metal&plastic.

FAQ

1: Q: Can you introduce your working process and your advantages?

A: Thanks for your question, first we will ask for your drawing, requirement, QTY and more detailed information to understand

your demand and our engineer can offer the best solution according to these specifications. Sometimes we will offer the structure

improvement program when we find any issue with your design or any suggestion to keep the cost down. Then we can start

mould design and fabrication when the price settles down, and delivery time is approved. About our feature, we would like to

say 100% quality assurance and advantage facilities can give you strong support and our professional service will lead you to

make great progress on this project.

2: Q: Can you ensure your production lead time and stable quality in a long-term relationship?

A: Of course. Except for the Chinese New Year holiday, our shipment is always on schedule since our scientific work arrangements,

strong production competence, and our reliable employee.

Thanks for your attention, why not send us your inquiry now?

| Warranty: | 6 Months |

|---|---|

| Shaping Mode: | Injection Mould |

| Surface Finish Process: | Polishing |

| Mould Cavity: | Single Cavity |

| Plastic Material: | PA |

| Process Combination Type: | Progressive Die |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

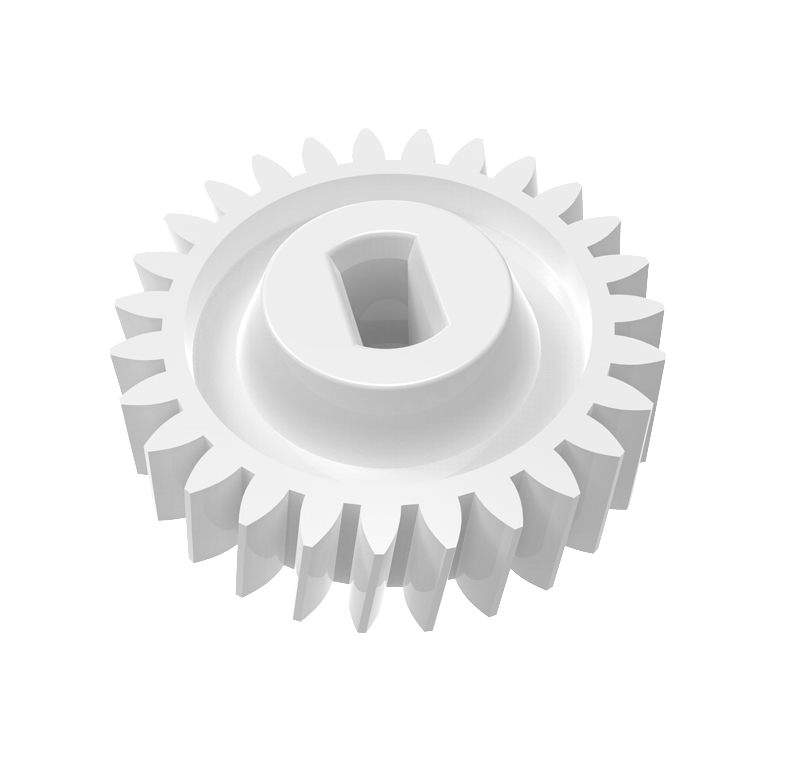

How do plastic gears contribute to reducing noise and vibration?

Plastic gears contribute to reducing noise and vibration in various applications. Here’s a detailed explanation of how they achieve this:

Plastic gears possess inherent properties that help dampen noise and vibration during operation. These properties, combined with specific design considerations, contribute to the reduction of noise and vibration in the following ways:

- Damping Characteristics: Plastic materials have inherent damping characteristics, meaning they have the ability to absorb and dissipate vibrations. When compared to metal gears, which are stiffer and transmit vibrations more efficiently, plastic gears can effectively reduce the transmission of vibrations through their damping properties.

- Reduced Resonance: Plastic gears have the ability to attenuate resonant frequencies, which are frequencies at which vibrations can be amplified. By properly designing the tooth profile, gear geometry, and material selection, plastic gears can shift or dampen these resonant frequencies, preventing excessive vibration and noise generation.

- Tighter Gear Mesh Tolerances: Plastic gears can be manufactured with tighter gear mesh tolerances, which refers to the amount of clearance or backlash between mating gear teeth. Tighter tolerances lead to better gear engagement and reduced impact or vibration during gear meshing, resulting in quieter operation.

- Surface Finishes: The surface finish of plastic gears can be optimized to reduce friction and noise. Smoother gear surfaces reduce the potential for gear tooth noise and improve the overall meshing characteristics between gears. Proper lubrication or the use of self-lubricating plastic materials can further enhance the noise-reducing properties.

- Flexibility in Tooth Design: Plastic gears offer greater flexibility in tooth design compared to metal gears. Engineers can optimize the tooth profile and modify the gear geometry to minimize noise and vibration. For example, incorporating modifications such as profile shifting, tip relief, or helical teeth can help reduce gear noise by promoting smoother and more gradual tooth engagements.

By leveraging these characteristics and design considerations, plastic gears can effectively reduce noise and vibration levels in various applications. This makes them particularly suitable for use in noise-sensitive environments, such as consumer electronics, automotive components, or office equipment.

It’s important to note that while plastic gears can contribute to noise and vibration reduction, the specific noise performance also depends on other factors within the overall system, such as gear arrangement, supporting structures, and the presence of other noise sources. Therefore, a holistic approach to noise reduction should be considered when incorporating plastic gears into a design.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

Are there different types of plastic materials used for making gears?

Yes, there are different types of plastic materials used for making gears. Here’s a detailed explanation of some commonly used plastic materials in gear manufacturing:

- Acetal (Polyoxymethylene – POM): Acetal is a popular choice for gear applications due to its excellent strength, dimensional stability, low friction, and wear resistance. It has good machinability and can be easily molded into gears with precise tooth profiles. Acetal gears offer low noise operation and have good resistance to moisture and chemicals. They are commonly used in automotive, consumer electronics, and industrial applications.

- Polyamide (Nylon): Polyamide or nylon is another widely used plastic material for gears. It offers good mechanical properties, including high strength, toughness, and impact resistance. Nylon gears have low friction characteristics, good wear resistance, and self-lubricating properties. They are commonly used in applications such as automotive components, power tools, and industrial machinery.

- Polyethylene (PE): Polyethylene is a versatile plastic material that can be used for gear applications. It offers good chemical resistance, low friction, and excellent electrical insulation properties. While polyethylene gears may have lower strength compared to other plastic materials, they are suitable for low-load and low-speed applications, such as in light-duty machinery, toys, and household appliances.

- Polypropylene (PP): Polypropylene is a lightweight and cost-effective plastic material that finds applications in gear manufacturing. It offers good chemical resistance, low friction, and low moisture absorption. Polypropylene gears are commonly used in various industries, including automotive, consumer electronics, and household appliances.

- Polycarbonate (PC): Polycarbonate is a durable and impact-resistant plastic material used for gears that require high strength and toughness. It offers excellent dimensional stability, transparency, and good resistance to heat and chemicals. Polycarbonate gears are commonly used in applications such as automotive components, electrical equipment, and machinery.

- Polyphenylene Sulfide (PPS): Polyphenylene sulfide is a high-performance plastic material known for its excellent mechanical properties, including high strength, stiffness, and heat resistance. PPS gears offer low friction, good wear resistance, and dimensional stability. They are commonly used in demanding applications such as automotive transmissions, industrial machinery, and aerospace equipment.

These are just a few examples of the plastic materials used for making gears. The choice of plastic material depends on the specific requirements of the gear application, including load capacity, operating conditions, temperature range, chemical exposure, and cost considerations. It’s important to select a plastic material that offers the necessary combination of mechanical properties and performance characteristics for optimal gear performance.

editor by CX 2023-11-06