Product Description

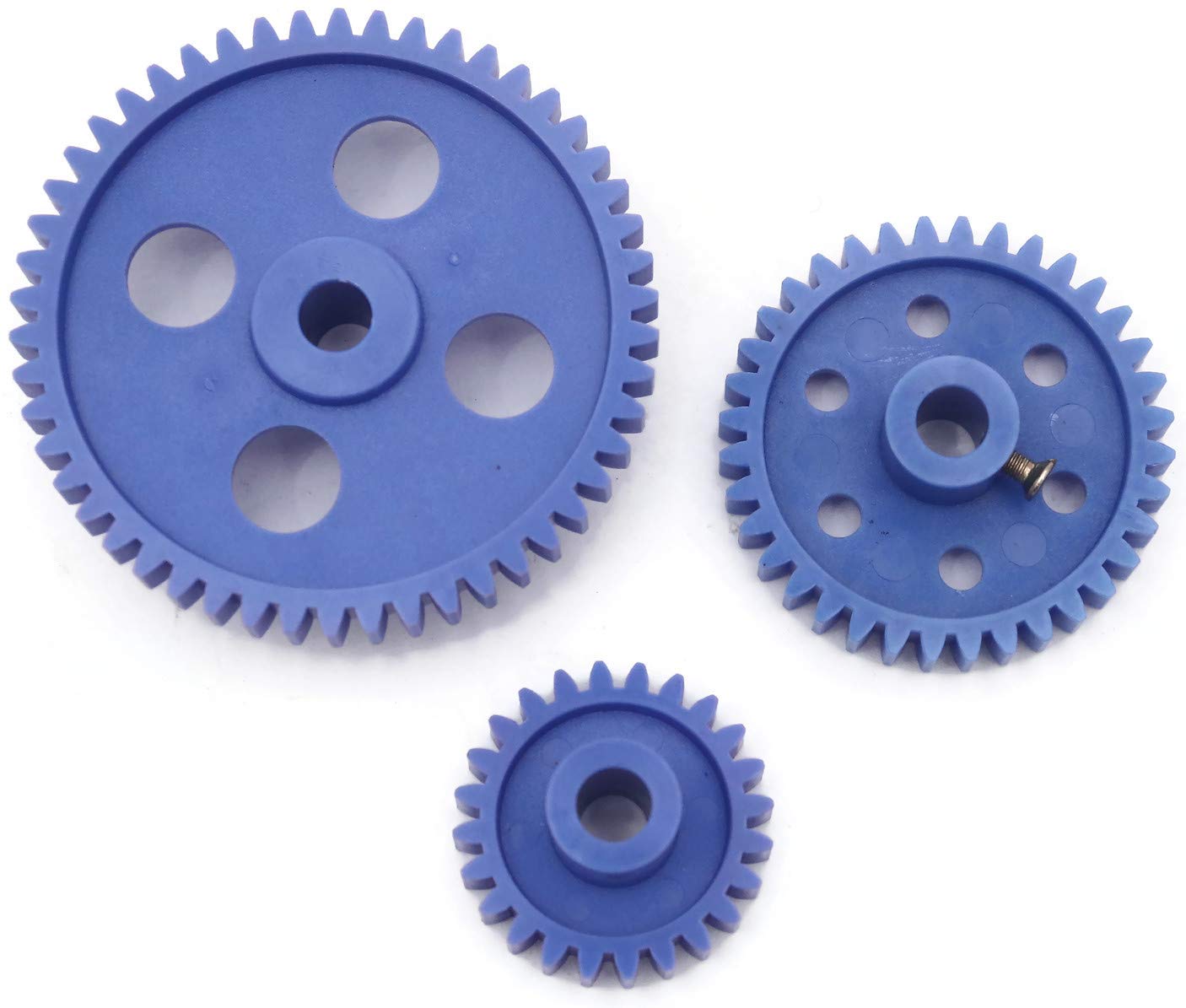

Good Quality High Precision Plastic CHINAMFG Wheel Pinion Bevel Gear

The precision of CHINAMFG gear grinding precision gear can reach 5~6 levels. The corresponding dimensional accuracy can be achieved through precision gear grinding machine and grinder. It has the characteristics of stable transmission, low noise, long service life, and is suitable for high-power and heavy load.

Product Parameters

| Product name | Spur Gear & Helical Gear & Gear Shaft |

| Customized service | OEM, drawings or samples customize |

| Materials Available | Stainless Steel, Carbon Steel, S45C, SCM415, 20CrMoTi, 40Cr, Brass, SUS303/304, Bronze, Iron, Aluminum Alloy etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Conditioning, Carburizing and Quenching,Tempering ,High frequency quenching, Tempering, Blackening, QPQ, Cr-plating, Zn-plating, Ni-plating, Electroplate, Passivation, Picking, Plolishing, Lon-plating, Chemical vapor deposition(CVD), Physical vapour deposition(PVD)… |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Printing Equipment Industry, Laser Equipment Industry, Automated Assemblyline Industry, Woodening Industry, Packaging Equipment Industry, Logistics storage Machinery Industry, Robot Industry, Machine Tool Equipment Industry |

Company Profile

Packaging & Shipping

FAQ

| Main markets | North America, South America,Eastern Europe,Weat Europe,North Europe.South Europe,Asia |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you! |

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the limitations of using plastic gears in industrial settings?

Using plastic gears in industrial settings has certain limitations. Here’s a detailed explanation of these limitations:

- Lower Load Capacity: Plastic gears generally have lower load-bearing capacities compared to metal gears. They are more susceptible to deformation and wear under heavy loads or high torque conditions. This makes them less suitable for applications that require withstanding substantial forces or transmitting high power.

- Temperature Sensitivity: Plastic gears have temperature limitations, and their performance can be affected by temperature variations. Some plastic materials may experience dimensional changes, loss of strength, or reduced stiffness at elevated temperatures. Additionally, high temperatures can accelerate wear and reduce the lifespan of plastic gears. Therefore, plastic gears may not be suitable for applications that involve high-temperature environments or extreme temperature fluctuations.

- Environmental Sensitivity: Plastic gears can be sensitive to certain environmental conditions. Certain plastic materials may degrade or become brittle when exposed to specific chemicals, solvents, oils, or UV radiation. This restricts their use in applications where exposure to harsh chemicals, lubricants, or outdoor elements is common.

- Wear and Abrasion: While plastic gears can offer good wear resistance, they are generally more prone to wear and abrasion compared to metal gears. Under heavy-load or high-speed conditions, the surface of plastic gears can wear down, leading to a decrease in performance and potential failure over time. Additional measures, such as incorporating reinforcements or using lubrication, may be necessary to mitigate wear in certain applications.

- Dimensional Stability: Plastic materials can have lower dimensional stability compared to metals. They may experience creep, shrinkage, or expansion over time, which can affect the accuracy and reliability of gear operation, particularly in applications with tight tolerances or precise gear meshing requirements.

- Impact Resistance: Plastic gears may have limited impact resistance compared to metal gears. They can be more susceptible to damage or fracture when subjected to sudden impact or shock loads. This makes them less suitable for applications with high impact or heavy-duty requirements.

- Compatibility with Existing Systems: In some cases, replacing metal gears with plastic gears may require modifications to the existing system. Plastic gears may have different dimensions, mounting requirements, or gear ratios compared to metal gears, necessitating design changes or adaptations to accommodate the use of plastic gears.

Despite these limitations, plastic gears can still offer significant advantages in certain industrial settings, such as reduced weight, noise reduction, and cost-effectiveness. It’s crucial to carefully evaluate the specific application requirements and consider the trade-offs between the benefits and limitations of plastic gears when deciding whether they are suitable for a particular industrial setting.

What is the impact of temperature variations on plastic gears?

Temperature variations can have a significant impact on plastic gears. Here’s a detailed explanation of their effects:

1. Thermal Expansion: Plastic gears can experience thermal expansion or contraction with changes in temperature. Different types of plastics have varying coefficients of thermal expansion, meaning they expand or contract at different rates. This can result in dimensional changes, which may affect the gear’s meshing, clearance, and overall performance. It’s important to consider the thermal expansion characteristics of the specific plastic material used in the gear design.

2. Material Softening or Hardening: Plastic materials can exhibit changes in mechanical properties with temperature variations. In general, as temperature increases, plastic materials tend to soften and become more flexible, while at lower temperatures, they can become stiffer and more brittle. These changes can impact the gear’s load-bearing capacity, wear resistance, and overall durability. It’s crucial to select plastic materials that can maintain their mechanical integrity within the expected temperature range of the application.

3. Dimensional Stability: Plastic gears may experience dimensional changes or warping due to temperature fluctuations. Higher temperatures can cause plastic materials to deform, leading to misalignment, increased backlash, or reduced gear accuracy. Conversely, lower temperatures can cause contraction, resulting in tight clearances, increased friction, or gear binding. Proper design considerations, including material selection and gear geometry, can help mitigate the impact of temperature-induced dimensional changes.

4. Lubrication and Wear: Temperature variations can affect the lubrication properties of plastic gears. Higher temperatures can cause lubricants to degrade or become less effective, leading to increased friction, wear, and potential gear failure. Similarly, low temperatures can cause lubricants to thicken or solidify, hindering proper lubrication and increasing wear. Selecting lubricants suitable for the anticipated temperature range and periodic maintenance can help ensure proper lubrication and minimize wear on plastic gears.

5. Cold Flow and Creep: Some plastic materials, especially those with lower glass transition temperatures, may exhibit cold flow or creep at elevated temperatures. Cold flow refers to the gradual deformation or flow of plastic material under constant stress, while creep refers to the time-dependent deformation under a constant load. These phenomena can cause changes in gear geometry, tooth profile, or tooth engagement over time, potentially affecting gear performance and functionality. Understanding the material’s creep and cold flow characteristics is important when selecting plastic gears for applications exposed to temperature variations.

6. Impact on Lubricants and Seals: Temperature variations can also impact the performance of lubricants and seals used in gear systems. Extreme temperatures can cause lubricants to break down, lose viscosity, or leak from the gear assembly. Seals and gaskets may also be affected, leading to compromised gear housing integrity or increased friction. It’s crucial to consider temperature compatibility and select appropriate lubricants and seals that can withstand the anticipated temperature range.

In summary, temperature variations can significantly impact plastic gears by causing thermal expansion, material softening or hardening, dimensional changes, lubrication issues, cold flow or creep, and effects on lubricants and seals. Proper material selection, design considerations, and understanding the anticipated temperature range are essential to ensure the reliable and optimal performance of plastic gears in various applications.

How do plastic gears differ from metal gears in terms of performance?

Plastic gears and metal gears exhibit differences in performance characteristics. Here’s a detailed explanation of how plastic gears differ from metal gears:

Strength and Durability:

- Metal gears are generally stronger and more durable compared to plastic gears. They can withstand higher torque, heavy loads, and harsh operating conditions. Metal gears are commonly used in applications that require high strength and durability, such as heavy machinery, automotive transmissions, and industrial equipment.

- Plastic gears have lower strength and may not be suitable for applications with high torque or heavy loads. However, advancements in plastic materials and manufacturing techniques have resulted in the development of high-performance plastics that offer improved strength and durability, allowing plastic gears to be used in a wider range of applications.

Weight:

- Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is advantageous in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Metal gears are heavier due to the density and strength of the metal materials used. While the weight of metal gears can provide benefits in certain applications that require high inertia or increased stability, it may also result in additional energy consumption and higher stresses on supporting structures.

Noise and Vibration:

- Plastic gears have inherent damping properties that help reduce noise and vibration levels during operation. This makes them suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Metal gears tend to generate more noise and vibration due to their higher stiffness. While there are methods to reduce noise in metal gears through design modifications and the use of noise-dampening materials, plastic gears generally offer better inherent noise and vibration reduction.

Wear and Lubrication:

- Plastic gears have the advantage of self-lubrication due to certain plastic materials having inherent lubricating properties. This reduces friction and wear between gear teeth, eliminating the need for external lubrication and simplifying maintenance requirements.

- Metal gears typically require lubrication to reduce friction and wear. Proper lubrication is essential for their performance and longevity. Insufficient or inadequate lubrication can lead to increased wear, heat generation, and even gear failure.

Corrosion Resistance:

- Plastic gears can exhibit excellent resistance to corrosion and chemicals, depending on the chosen plastic material. This makes them suitable for applications in corrosive environments where metal gears may suffer from degradation or require additional protective measures.

- Metal gears may corrode when exposed to moisture, chemicals, or certain operating environments. Corrosion can weaken the gears and compromise their performance and lifespan. However, corrosion-resistant metals or protective coatings can mitigate this issue.

Design Flexibility:

- Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Metal gears are more limited in terms of design flexibility due to the constraints of machining or shaping metal materials. While metal gears can still be customized to some extent, the process is generally more time-consuming and costly compared to plastic gear manufacturing.

It’s important to consider these performance differences when selecting between plastic and metal gears for a specific application. The requirements of the application, including load capacity, operating conditions, noise considerations, and durability expectations, should guide the choice of gear material.

editor by CX 2023-10-31